Stuth

| Corp | Alùmanum (5050 5052 5056 5154) | (AL Mg 1% -1.5%, 2% -2.5% ,3% -3.5%,5%) | ||

| Crìochnaich | Snasail | Dath RAL air a pheantadh | ||

| Mandrel | Aluminium ● | Stàilinn | Stàilinn nach meirg | |

| Crìochnaich | Snasail ● | Zinc Plated | Snasail | |

| Seòrsa Ceann | Dome, CSK, Flange Mòr | |||

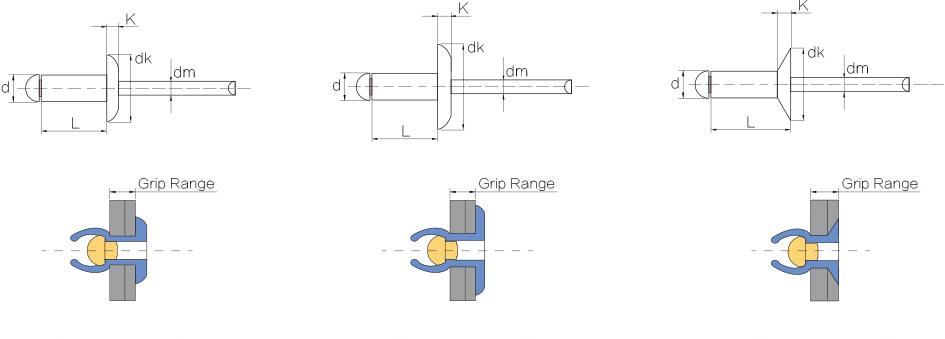

Sònrachadh

| D1 NOM. | DRILL NO. &MÒR THOILL | ART.CODE | RANNSACHADH GRIP | L(MAX) | D NOM. | K MAX. | P MIN. | SHEAR LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 n |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 120 530 n | 150 670 n |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0. 312" 7.9 | 0.050" 1.27 | 1.06" 27 | 190 850 n | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1. 175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 260 1160 n | 320 1430 n |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1. 325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1,000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1. 125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1. 375 | 34.9 | |||||||

Iarrtas

Bidh an t-seam fosgailte làn alùmanum againn a’ cleachdadh uèirichean alloy alùmanum àrd-inbhe.An dèidh an t-sreap, Cha mheirg e gu bràth.an coimeas ri seamannan àbhaisteach, tha an dian rivet ìosal, agus mar sin tha e freagarrach airson an stuth bog a tha ceangailte. alu mg 2% 2.5% 3.5% agus 5% (5052 5154 5056).

Tha na buannachdan aig seamannan pop seòrsa fosgailte Fixpal airson obrachadh furasta, sàrachadh sàr-mhath, coltas brèagha, feartan corporra àrd.Roghainn foirfe de riveting aon-taobhach. Faodar seamannan pop alùmanum a chleachdadh gu farsaing ann an grunn charbadan, soithichean, saothrachadh innealan, eileagtronaigeach, ionnsramaid, innealan bìdh, uidheamachd meidigeach, togail, sgeadachadh agus raointean ceangail eile.

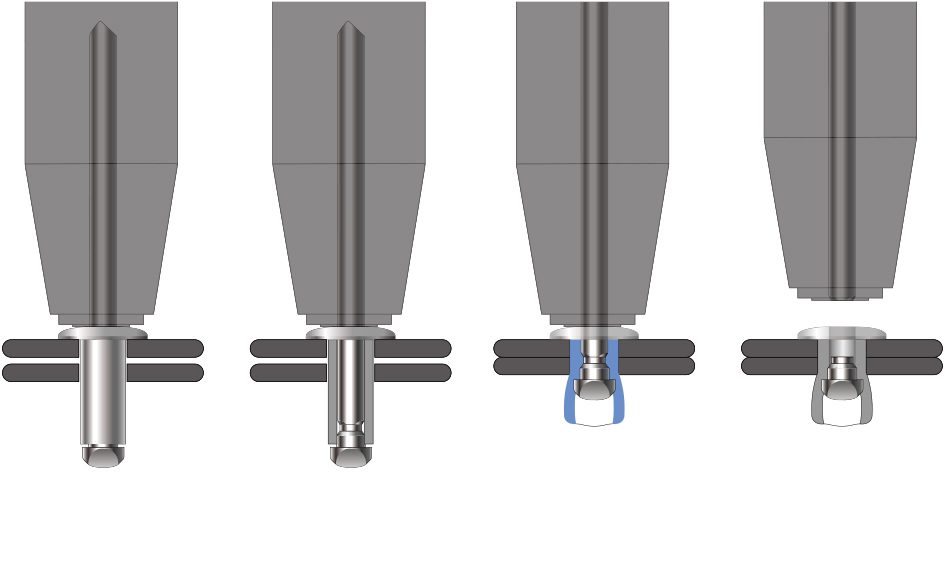

Na duilgheadasan agus na h-adhbharan nuair a bhios tu a 'cleachdadh seam dall:

1. Burrs: Às deidh a bhith a 'sreap, bidh am mandrel briste le burrs a' dol tro na tuill sèididh;no bidh na tuill shnaidhte a’ sruthadh bhon taobh a-muigh gus spatula burr a chruthachadh.

adhbhar nan burrs: tha trast-thomhas an mandrel beag;tha an stuth rivet bog;tha trast-thomhas toll drileadh an obair-obrach ro mhòr;tha mion-chomharrachadh muzzle a’ ghunna rivet ro mhòr;

2. Tuitidh ceann na h-ingne dheth: Às deidh an t-seam a bhith air a tharraing, chan urrainnear ceann an t-sèididh a phasgadh agus tuitidh e bhon t-seam.

Is e na h-adhbharan airson a bhith a’ tuiteam ceann rivet a ’chridhe: tha trast-thomhas a’ chaip ìnean ro mhòr;tha an t-seamrag nas giorra, agus chan eil tiugh an t-seamrag a’ freagairt.

3. an t-seamrag a' sgàineadh: Às dèidh an t-sèididh, tha an t-seamrag air a sgoltadh no air a bhriseadh gu tur.

Is e na h-adhbharan airson a bhith a’ sgàineadh an t-seamrag: cus cruas às deidh làimhseachadh neo-sheasmhach no gun teasachadh, tha an ad cridhe ìnean ro mhòr.